China Leads Global Humanoid Robot Shipments (90% in 2025)—Amazon’s $4.6BN Fail, $7.999 Laundry Bots Spark Debate

TL;DR

- Amazon Halts Blue Jay Robot Project Amid High Costs and Complexity

- China's Humanoid Robots Dominate Spring Festival Gala, Signal Industrial Policy Shift

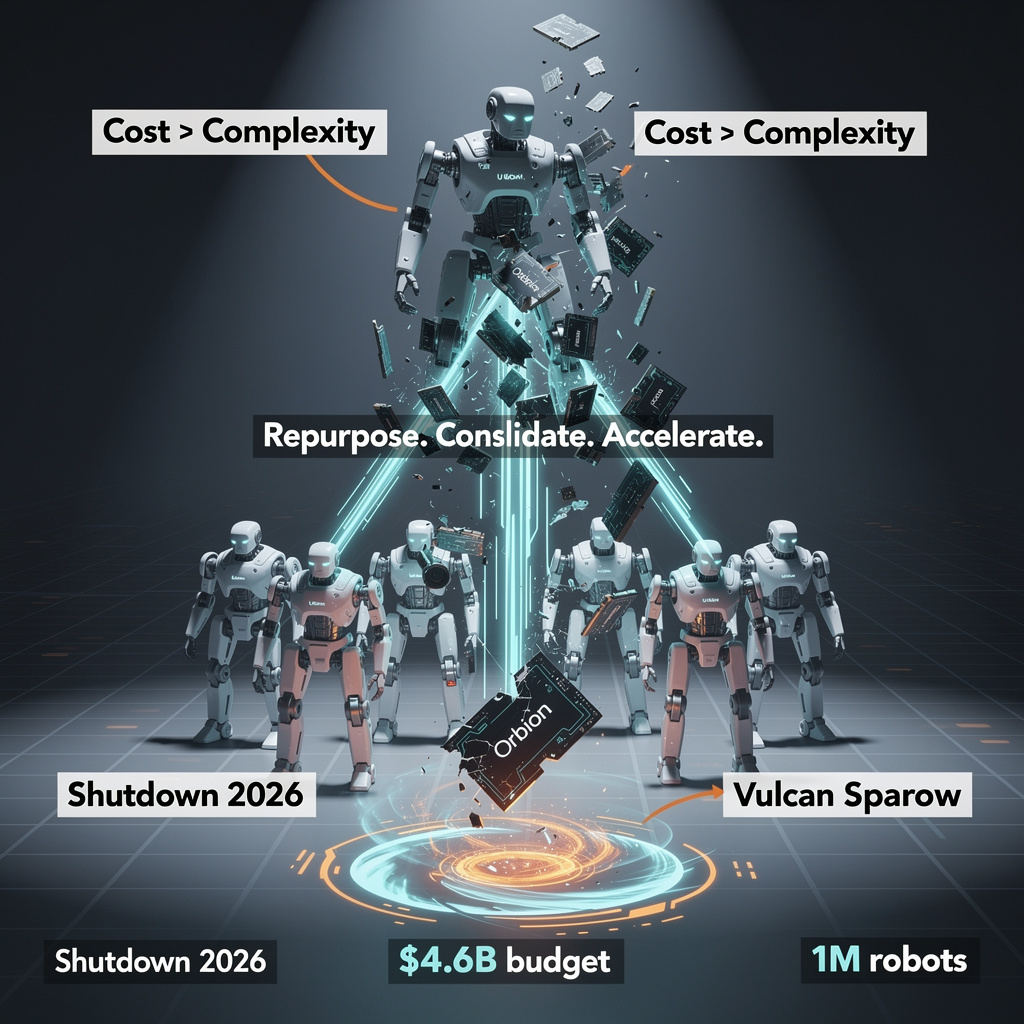

🤖 Amazon Scraps $4.6BN Blue Jay Robot Pilot in Milpitas—Shifting to Proven Scalable Platforms

Amazon spent $4.6BN on humanoid robot developers in 2025 but just shut down its Blue Jay warehouse robot pilot—enough to fund 250,000 new robots (the same number Amazon added last year), 🤖. The Milpitas project’s modular design required custom software/hardware not standardized across Amazon’s 1M-robot fleet, driving up integration costs. Instead, Amazon’s migrating Blue Jay tech to proven platforms like Vulcan and Sparrow—choosing scalability over experimental modularity. Warehouse staff in Milpitas (who lost a same-day delivery boost) and rivals like Boston Dynamics (with less competition) feel the impact—how would your local warehouse shift if Amazon prioritized experimentation over proven tech?

Amazon has shut down its Blue Jay warehouse robot project—just three months after launching it in Milpitas, California—citing "high operational costs and technical complexity" as the final nail in the coffin. The initiative, designed to slash same-day delivery latency at the DUR3 station, was terminated in January 2026 and officially announced February 17; core technologies will now fuel more established Amazon Robotics platforms like Vulcan and Sparrow. The move is a textbook example of Big Tech’s robotics dilemma: experimental innovation often stalls when scalability and cost collide.

Why Blue Jay Failed: Cost and Complexity Headwinds

Two factors doomed Blue Jay from the start. First, operational expense: while Amazon didn’t disclose exact figures, its 2025 robotics budget—$4.6 billion spent on humanoid developers alone—highlights the scale of investment at stake. Second, technical integration hell: Blue Jay’s modular "Orbion" design required custom software and hardware interfaces not standardized across Amazon’s fleet of 1 million robots. Its edge AI stack, meant to handle real-time delivery decisions, demanded massive labeled datasets that clashed with Amazon’s existing data infrastructure, slowing training compared to predecessors like Robin and Sparrow.

The Robot That Wasn’t: Blue Jay’s Technical DNA

Blue Jay’s pitch was flexibility: a modular system with interchangeable perception, actuation, and power modules, designed to adapt to warehouse layouts without overhauls. But that flexibility came with a cost. Unlike Vulcan (proven for high-throughput picking) or Sparrow (mobile intra-warehouse transport), Blue Jay’s parts didn’t plug into Amazon’s ecosystem—forcing engineers to build bespoke solutions from scratch. The result? A robot that was too niche to scale quickly, even as Amazon raced to meet its 75% global delivery automation target (already achieved in 2026).

What Amazon Gains (and Loses) From the Halt

The shutdown isn’t all losses. Operationally, Amazon avoids derailing its 10% order-to-dispatch latency reduction goal for Milpitas—though it sacrifices the pilot’s potential to supercharge same-day throughput. Safely, it preserves current collision-avoidance standards (already cutting human-robot risks) while avoiding untested Blue Jay designs. Financially, it slashes capital spending on a niche project, redirecting funds to platforms with proven ROI. The trade-offs? A missed chance to gather field data on modular robotics, and short-term same-day delivery capacity gaps in the Western U.S.—until Amazon’s 2027 "Orbital" successor scales.

The Road Ahead: Amazon’s Robotics Timeline

Amazon’s post-Blue Jay strategy is simple: repurpose, consolidate, and accelerate.

- 0–12 Months: Blue Jay’s subsystems will be folded into Vulcan, Sparrow, and Proteus (Amazon’s flexible deployment platform) via incremental firmware updates—leveraging mature supply chains to minimize disruption.

- 1–3 Years: "Orbital," the 2027 modular follow-up, will inherit Blue Jay’s hardware but use Vulcan’s proven control stack, shrinking development timelines by years.

- 3–5 Years: Amazon aims to deploy modular robots in 1,000+ U.S. fulfillment centers, targeting 90% same-day delivery assistance—doubling down on its automation momentum.

When Innovation Meets Reality

Blue Jay’s death isn’t a failure of Amazon’s robotics vision—it’s a triumph of pragmatism. By ditching unproven modularity for proven scalability, the company is betting that repurposed tech will one day deliver on the same-day dream without the chaos. For the robotics sector, this is a warning: even the boldest ideas need to fit the machine. Amazon’s move reminds us that in automation, reliability isn’t just a feature—it’s the entire point.

🤖 China’s 90% Global Humanoid Robot Share: Policy-Backed Dominance Amplified by Spring Festival Gala

China holds 90% of global humanoid robot shipments (2025)—stunning dominance that means nearly all global humanoid robots sold last year were made here 🤖 Beijing didn’t just stop at numbers: they used the Spring Festival Gala (1B+ viewers) to normalize the tech, attract $14M in partnerships, and signal a policy shift to mass production. But here’s the tension: will this scale outpace safety standards, or leave foreign firms playing catch-up? Chinese startups (Unitree, MagicLab), domestic factories, and global competitors alike are watching—how might this shake up robotics in YOUR region?

China’s Humanoid Robot Gala Stunt Signals a Bold Industrial Policy Shift

Over 1 billion viewers watched four Chinese robotics firms—Unitree, Magiclab, Galbot, and Noetix—unveil humanoid robots performing martial arts, folk dances, and comedy sketches during the 2026 Spring Festival Gala. The event wasn’t just entertainment: it was a strategic showcase of Beijing’s push to mainstream humanoid robotics as a cornerstone of its industrial policy, backed by $14 million in partnerships and a clear signal that China is shifting from lab prototypes to mass-market, culturally integrated robotic systems.

How the Robots Worked (and Why It Matters)

The demos weren’t gimmicks—they proved technical leapfrogging. Unitree’s G1 pulled off nunchaku combat, 3-meter trampoline jumps, and 14 km/h sprints; MagicLab’s Z1 did a 360° “Thomas spin”; Galbot handled voice recognition, object retrieval, and laundry folding; Noetix’s Bumi starred in a comedy sketch with humans. Underpinning this was advanced motion-control and balance algorithms enabling parkour, wall-flips, and back-flips—moving beyond isolated lab tests to real-world integration.

The Impacts: From Market Share to Mainstream Acceptance

- Market Dominance: China controls ~90% of global humanoid shipments (13,000 units in 2025); 2026 projections call for 28,000+ units (60% CAGR through 2028).

- Policy Visibility: The 1 billion+ viewer gala turned humanoids into household names, boosting investment—Unitree aims to scale from 5,500 (2025) to 10,000–20,000 (2026) units.

- Tech Integration: Partnerships linked robots to AI (ByteDance’s Doubao) and suppliers (CATL), reinforcing China’s “hardware-software” model and reducing foreign component reliance.

- Consumer Acceptance: Unitree’s viral martial-arts routine drew 13.5 billion post-clip views, proving cultural integration drives mainstream adoption.

Strengths, Gaps, and Risks

Strengths include a massive domestic audience, top political endorsement (Xi Jinping, NDRC), funding (Shoucheng Holdings), and fast hardware iteration. Weaknesses: concentrated startups, unproven reliability in unstructured environments, nascent safety rules. Opportunities: export to emerging markets, factory assembly deployments, RaaS for elder care/hospitality. Threats: international data pushback, IP disputes, Western competition (Tesla’s Optimus), actuator supply chains.

The Road Ahead: 0–5 Years

- 0–12 Months: Finalize $100M CNY partnerships; Unitree IPOs in Shanghai ($6–7B valuation); more TV product placements.

- 1–3 Years: 10k–20k units/year (30% cost cuts via modular parts); “robotic brains” in 5–10 factories; 2k–5k exports to SE Asia/Africa.

- 3–5 Years: NDRC safety standards (like ISO 10218-3); AI-integrated service robots boost RaaS; market consolidation via acquisitions.

The Big Picture: China’s Robotics Bet

The gala wasn’t a one-off—it was a deliberate industrial policy tool. By merging mass media, state subsidies, and production targets, China is institutionalizing humanoid robotics as a “smart manufacturing” pillar. If successful, it won’t just lead in units—it will set global standards for safety, control, and AI. The question now: Can China sustain this with diverse players and proven reliability? Either way, humanoid robots are no longer futuristic—they’re part of China’s industrial present.

In Other News

- Meta’s 'Name Tag' Smart Glasses Face Regulatory and Privacy Backlash Ahead of Launch

- Pentagon Threatens to Cut Ties with Anthropic Over Military AI Use Restrictions

- Apple Accelerates Development of AI-Powered Wearables: Smart Glasses, AI Pendant, and Enhanced AirPods

Comments ()